| Grade | Gel Strength | Moisture | Whiteness |

|---|---|---|---|

| SA | 800/1000 | Less then 76% | 46 UP |

| SA | 800 / 1000 | Less than 76% | 46 UP |

| A | 400/600 | Less Then 77% | 44 UP |

| KA | 200/400 | Less Then 77% | 42 UP |

| C | 200/400 | Less Then 77% | 40 UP |

| Grade | Gel Strength | Moisture | Whiteness |

|---|---|---|---|

| AA | 600/800 | Less then 76% | 45 UP |

| A | 400/600 | Less than 77% | 45 UP |

| KA | 200/400 | Less Then 77% | 42 UP |

| C | 100/200 | Less Then 77% | 40 UP |

| Grade | Gel Strength | Moisture | Whiteness |

|---|---|---|---|

| A | 400/600 | Less than 76% | 40 UP |

| KA | 200/400 | Less Then 77% | 38 UP |

| C | 100/200 | Less Then 77% | 36 UP |

| Grade | Gel Strength | Moisture | Whiteness |

|---|---|---|---|

| SSA | 1000 UP | Less Then 76% | 47 UP |

| SSA | 800/1000 | Less Then 76% | 47 UP |

| AA | 600/800 | Less Then 76% | 47 UP |

| Grade | Gel Strength | Moisture | Whiteness |

|---|---|---|---|

| SSA | 1000 UP | Less Then 76% | 46 UP |

| SA | 800/1000 | Less Then 76% | 46 UP |

| AA | 600/800 | Less Then 76% | 46 UP |

| A | 400/600 | Less Then 77% | 45 UP |

| KA | 200/400 | Less Then 77% | 45 UP |

| Grade | Gel Strength | Moisture | Whiteness |

|---|---|---|---|

| SSA | 1000 UP | Less Then 76% | 46 UP |

| SA | 800/1000 | Less Then 76% | 46 UP |

| AA | 600/800 | Less Then 76% | 46 UP |

| A | 200/400 | Less Then 77% | 45 UP |

| Grade | Gel Strength | Moisture | Whiteness |

|---|---|---|---|

| SSA | 1000 UP | Less Then 76% | 46 UP |

| SA | 800/1000 | Less Then 76% | 46 UP |

| AA | 600/800 | Less Then 76% | 45 UP |

| A | 400/600 | Less Then 77% | 44 UP |

| KA | 200/400 | Less Then 77% | 42 UP |

| C | 100/200 | Less Then 77% | 40 UP |

The water is tested for bacteria in microbiology lab. The water is online tested for PH, hardness and temperature.

This is done initially on fish harbour by company appointed supervisor.

The raw material is again inspected in factory by another supervisor by taking 2 kg sample out of each 500 kg raw material.

The water is tested for bacteria in microbiology lab. The water is online tested for PH, hardness and temperature.

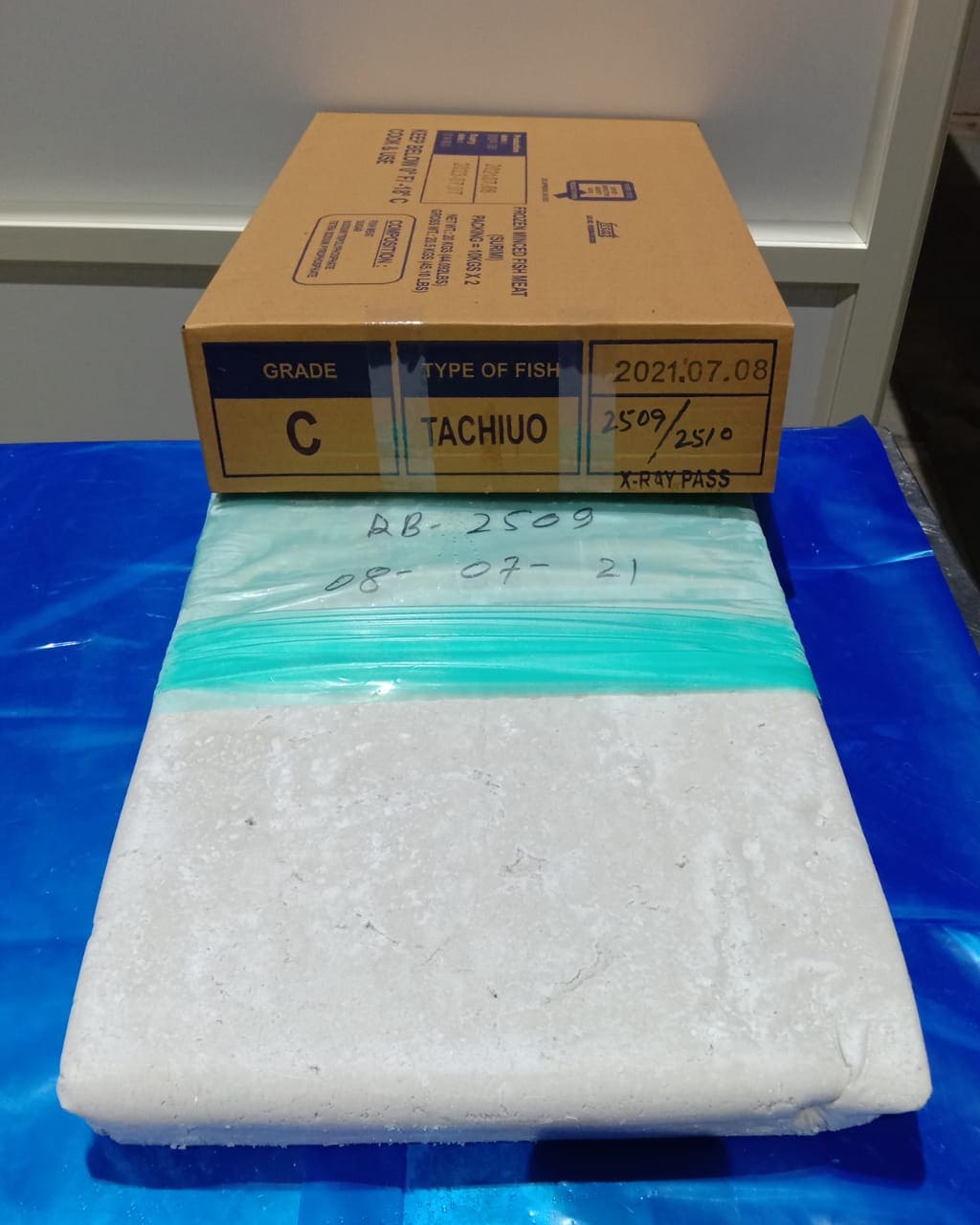

Each slab is passed through x−ray machine which gives our customer confidence on our product without contamination.

15 Kms from Mangalore Fishing Harbour

50 Kms from Malpe Fishing Harbour

10 Kms from New Mangalore Shipping Port

The raw material is loaded in ice fish ice condition in boxes in reefer vehicle owned by Yashaswi company to maintain temperature 5°c or below.

- In plant fish is washed with chilled water in 5°c and flake ice used to keep temperature.

- The chilled water (9°c) is used for fish meat washing in 3 leaching stages.

- The plate freezer freezes the surimi in 90 minutes to reach -18°c.

- These product is stored in cold storage for -18°c or below.

- The -18°c temperature is maintain in reefer container.

The city water is passed through cartridge filter of 10-micron size to prevent any contamination and then passed through ultraviolet treatment of rays. Again chlorine dosing is done at 2 ppm level to reduce bacterial load in water.

The water chilled to 5°c for washing of fish (raw material). The water is chilled at 9 to 100c to wash the meat in leaching tanks which prevents denaturation of proteins in processing stage.

The fish head, gut and solid waste are processed in fish meal so that we do zero waste discharge to environment.

The waste water is treated with diffused aeration flotation and then given anaerobic treatment to reduced waste water to CETP in prescribed limits.

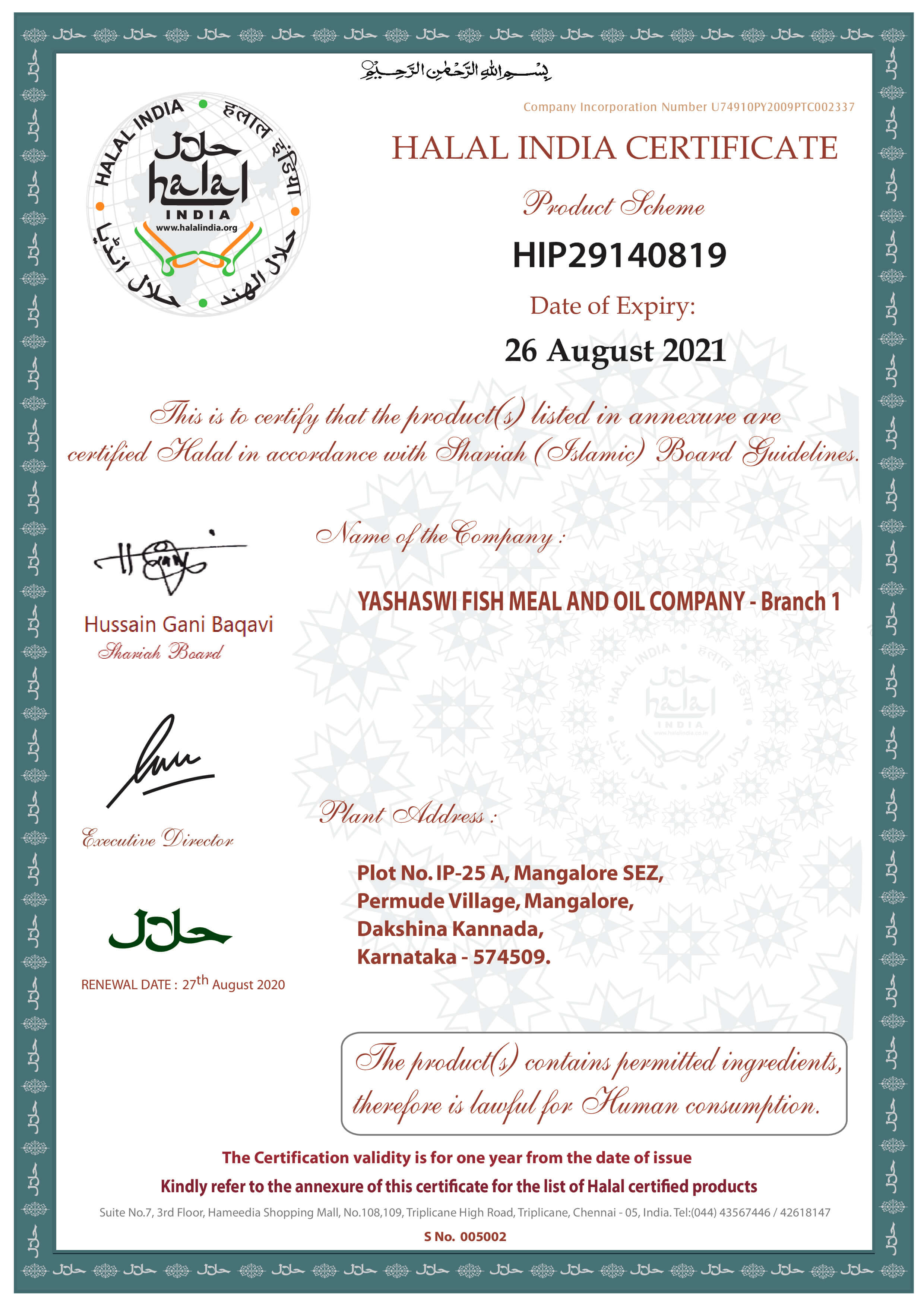

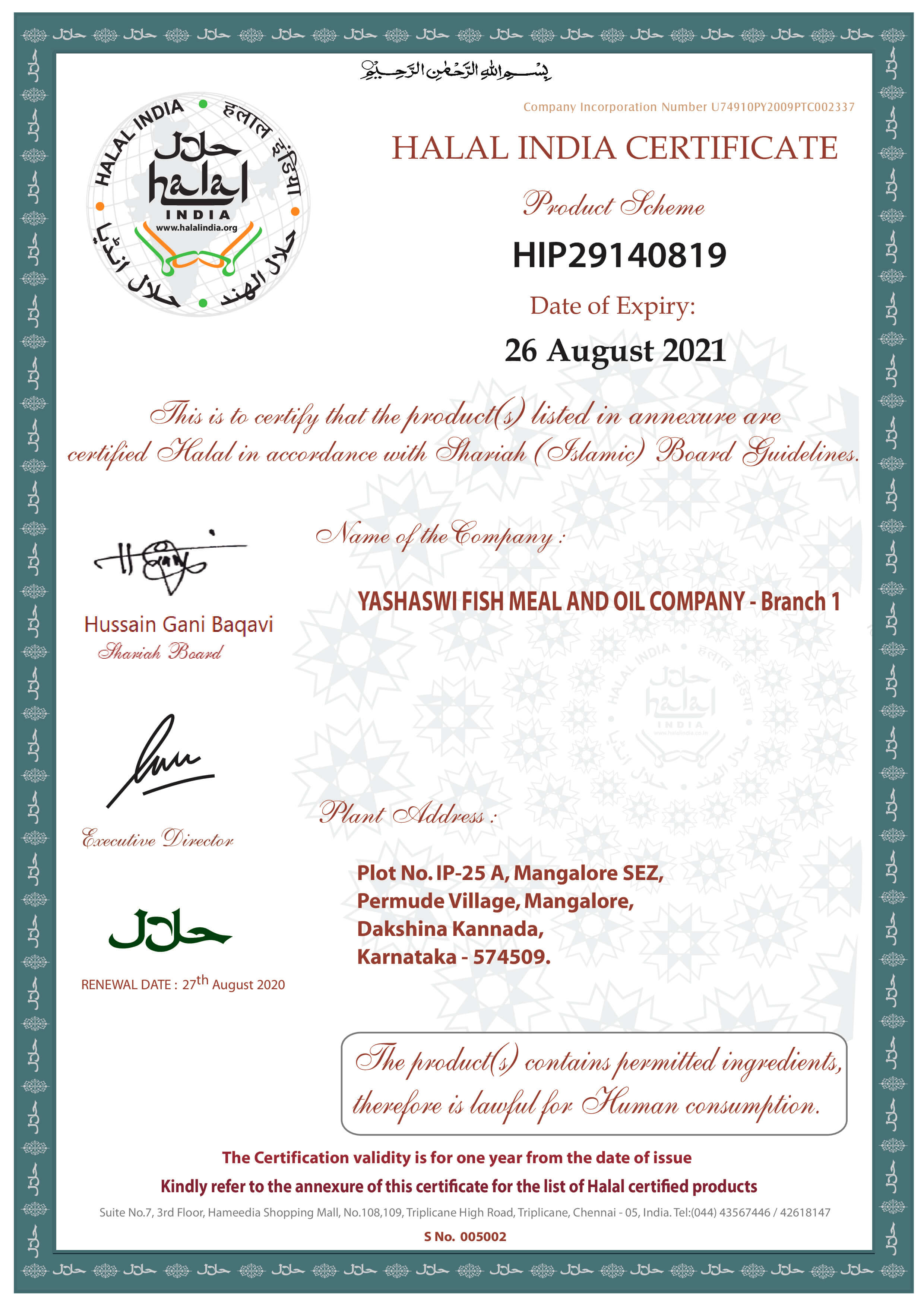

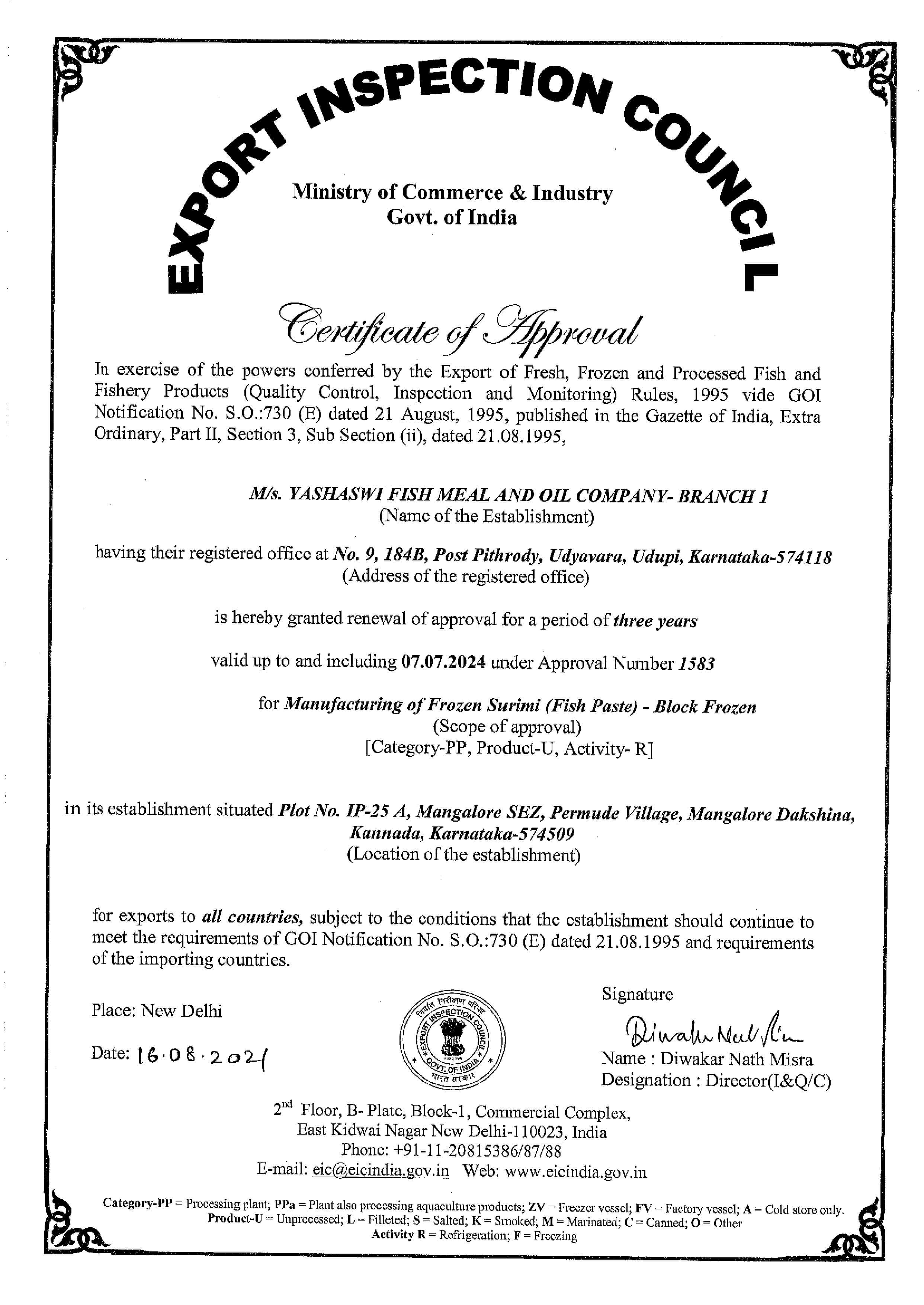

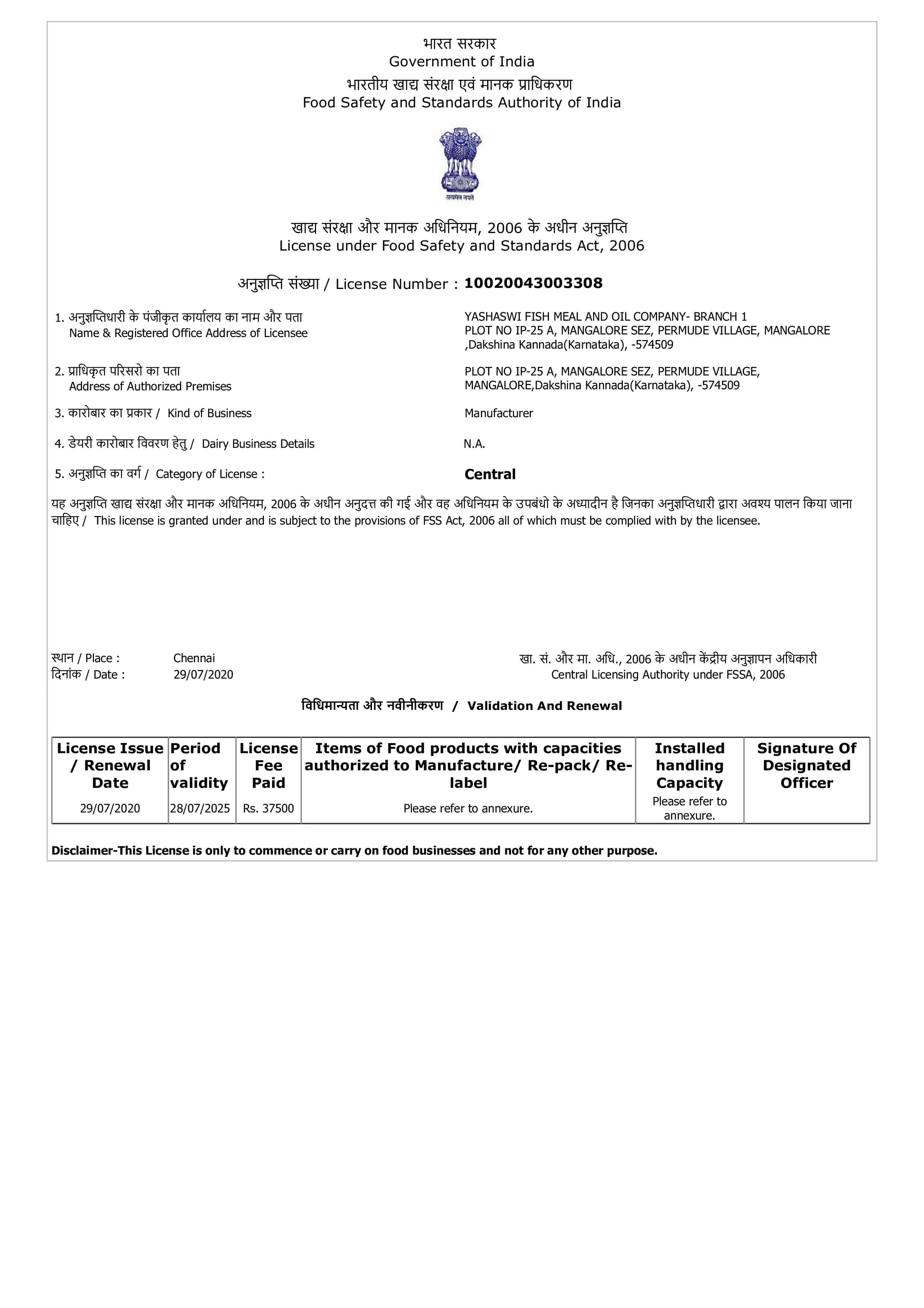

Yashaswi Fish Meal and Oil Company − Branch 1 Plot No. IP-25(A), Mangalore SEZ, Permude Village, Mangalore, Dakshina Kannada, Karnataka, India − 574509

G - Map Link

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud.

Yashaswi Surimi Marine is a subsidiary of Yashaswi Fish Meal & Oil Company, a leading manufacturer of Fish Meal and Fish Oil in Asia.

Being in the fish meal business for the last 15 years, apart from fish trading experience of 30 years, Yashaswi Group has got solid network of raw material procurement all over coastal India. As all of the Surimi processing plants are concentrated only in northern part of India, even though major fish landing centres are located in the Southern region, Yashaswi Group has thought of initiating Surimi processing plant of 20000 TPA in Mangalore, which is most strategic location in terms of procurement of Surimi raw materials from west as well as east coast of India throughout the year.

The making of Surimi begins with high quality, all natural ingredients. Our main ingredient is surimi made from premium quality Fish which is caught in the sea waters of the FAO Zone 051 and 057. Our Mangalore Surimi facility has been recognized and certified for meeting the industry’s highest standards for food safety, including FSSC, HACCP, EU and CU certification, the highest global standard for food safety. By meeting this standard, you can be confident that our product is safe and of high quality.

1. Source quality raw material from approved suppliers.

2. Provide accurate traceability.

3. Organize safe logistic.

4. Secure stable deliveries.

Yashaswi's vision is to provide best in quality Surimi with sustainable sourcing of raw material as priority and by being environmentally responsible.